-

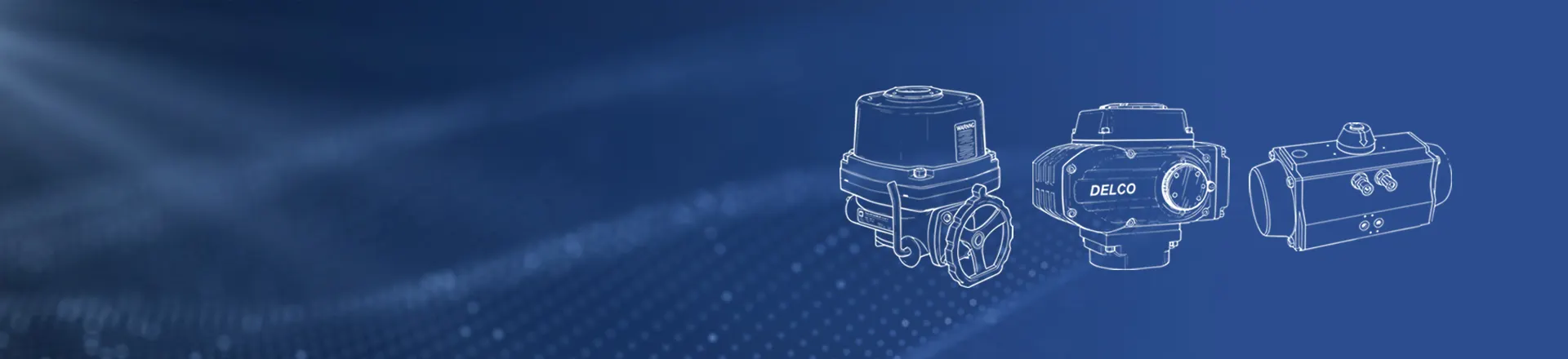

DELCO DKV-IP67 Small Electric Actuator High Torque (4000 N.m) & Wide Angle Control

Materiall: Aluminum alloy

Protection Grade: IP67

Type: On-Off, Regulation, Intelligent

-

DELCO DKS-IP67 Electric Actuator High Torque Corrosion Resistant Industrial Control

Materiall: Aluminum alloy

Protection Grade: IP66 / IP67

Type: On-Off, Regulation, Intelligent

-

DELCO DKQS-IP68 Submersible Electric Actuator - Heavy-Duty IP68 Automated Control

-

DK03 Series Small Electric Actuator - Highly Integrated, Compact, and Intelligent

-

DELCO AT Series Spring Return Pneumatic Actuator - Fail-Safe Emergency Control

-

DELCO AT Series Double-Acting Pneumatic Valve Actuator - High Cycle, Precise Control

-

DELCO AT Series Pneumatic Valve Actuator - with Solenoid Valve & Limit Switch Box

-

Z-Type Multi-Turn Electric Valve Actuator – Compact, Reliable & Intelligent Control

Materiall: Aluminum alloy

Protection Grade: IP65 / IP68

Type: On-Off, Regulation, Intelligent

-

High-Performance AT Series Pneumatic Actuator Double-Acting & Spring Return

-

DK Series High-Integrity Multi-Functional Electric Actuator for Industrial Valve Automation-Intelligent

Materiall: Aluminum alloy

Protection Grade:IP65

Type: On-Off,Regulation,Intelligent

What Are Valve Actuators?

Valve actuators are the critical components that automate valve operation, enabling precise control of fluid flow. Delco specializes in two major categories: Electric and Pneumatic actuators. Unlike manual handles or gearboxes, these devices provide the power and intelligence to open, close, or modulate valves remotely, making them essential for modern process automation. Engineered for durability and efficiency, Delco actuators optimize automation in oil, gas, water, and manufacturing systems—trusted for seamless performance.

Delco offers a complete portfolio of valve actuators, covering both major power sources to meet diverse operational needs:

|

|

|

|

|

|

|

| Compact and efficient design, providing precise 90-degree control for ball, butterfly, and plug valves. | Precise multi-rotation control, perfect for gate and globe valves requiring linear motion. | Certified safety design, ensuring reliable operation in hazardous and explosive environments. | Fully submersible construction, designed for reliable performance in underwater or flood-prone applications. | High-torque output design, providing robust control for large heavy-duty industrial valves. | Compact and durable mechanism, offering fast and reliable actuation for quarter-turn valves. |

Key Features & Advantages

When selecting actuators, Delco provides:

Engineering Selection by Application

Match valve design and actuator type with your industry needs.

| Comparison Factor | Electric Actuators (Motor Driven) | Pneumatic Actuators (Air Driven) |

|---|---|---|

| Power Source | Electricity (24VDC, 110/220/380VAC) | Compressed Air (3-8 Bar / 40-120 PSI) |

| Motion Speed | Slower & Controlled (10s - 100s) Adjustable speed prevents water hammer |

Fast & Instant (< 1s possible) Ideal for quick action & emergency shutdown (ESD) |

| Control Precision | High Precision (±0.5%) Perfect for 4-20mA flow modulation |

Moderate Requires additional Smart Positioner for modulation |

| Fail-Safe Mode | Complex Requires Battery Backup or Capacitor (higher cost) |

Simple & Reliable Spring Return automatically closes valve if air fails |

| Duty Cycle | Limited (typically 30% - 75%) Motor requires cooling periods (unless expensive continuous models used) |

High / Continuous (100%) Can cycle frequently without overheating constraints |

| Maintenance | Moderate Contains gears & electronics; complex to repair if failed |

Low Simple mechanical design ("Fit & Forget"); ultra-long cycle life |

| Best Application | Precision control loops, remote sites without air supply, HVAC | Hazardous zones (Explosion-proof by design), high-frequency cycling |

Get Engineering Support & OEM Solutions

-

Quick valve sizing recommendations

-

ISO, CE, ATEX certified production

-

Datasheets and 3D drawings available

-

OEM branding & packaging services

-

Material & sealing customization (PTFE, EPDM, metal)

-

Explosion-proof & modulating actuator options