Vertical Pneumatic Sanitary Butterfly Valve - 316L Clamp End (FDA/GMP) | DELCO

The DELCO Vertical Pneumatic Sanitary Butterfly Valve is specialized for sterile fluid control in vertical pipelines, offering a space-saving design with zero dead legs. Manufactured from 316L / 304 Stainless Steel with a mirror-polished finish (Ra ≤ 0.8μm), it fully complies with GMP and FDA standards. Featuring a Tri-Clamp connection for rapid disassembly, this valve supports CIP/SIP cleaning, making it ideal for biopharmaceutical, vaccine production, and dairy processing lines.

Size Range:DN40-DN1200

Size Range:DN40-DN1200

Material:Cast Iron, WCB, SS304/316 etc.

Material:Cast Iron, WCB, SS304/316 etc.

Connection Standard:GB / ANSI /JIS /DIN

Connection Standard:GB / ANSI /JIS /DIN

Technical Features

Designed for hygienic critical applications, this valve combines sterile compliance with vertical installation efficiency

✅Vertical Design for Space Saving & Residue Prevention:Specifically engineered for vertical pipelines, this unique structure minimizes the installation footprint compared to horizontal actuators. The vertical stem design prevents medium retention and ensures complete gravity drainage, eliminating the risk of cross-contamination in sterile batches.

✅FDA-Compliant Hygienic Surface (Ra ≤ 0.8μm):The valve body and disc are machined from high-purity Stainless Steel 304/316L. All fluid-contact surfaces undergo mirror polishing to Ra ≤ 0.8μm, ensuring no bacteria buildup. The design is free of dead corners, fully supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes.

✅Food-Grade Sealing System:Equipped with premium soft seals available in EPDM or Silicone (customizable to high-temp glue). These seals are compliant with food safety standards, providing excellent resistance to aging and sterilization cycles while ensuring a bubble-tight shutoff for high-value media like vaccines or dairy.

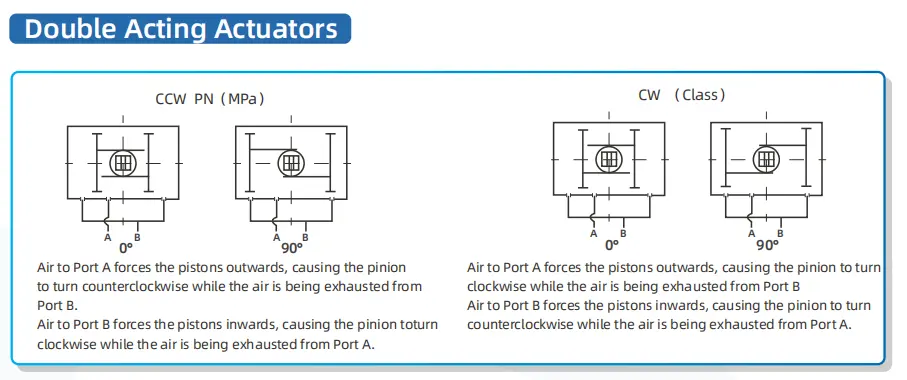

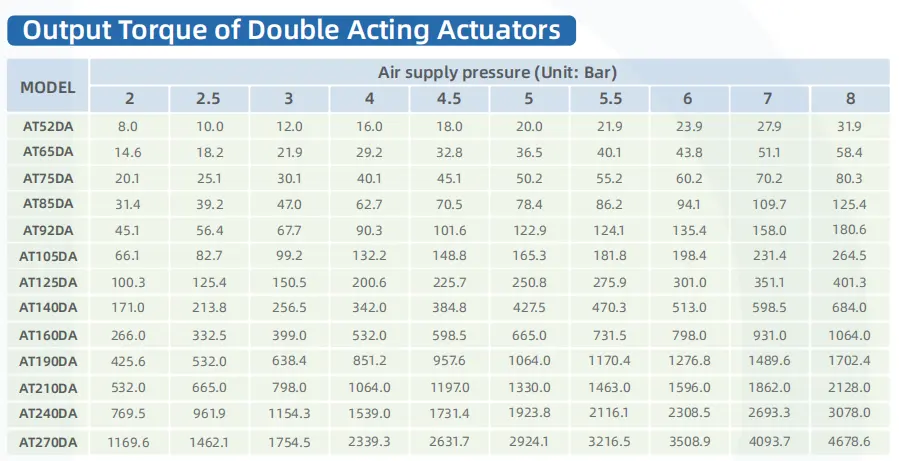

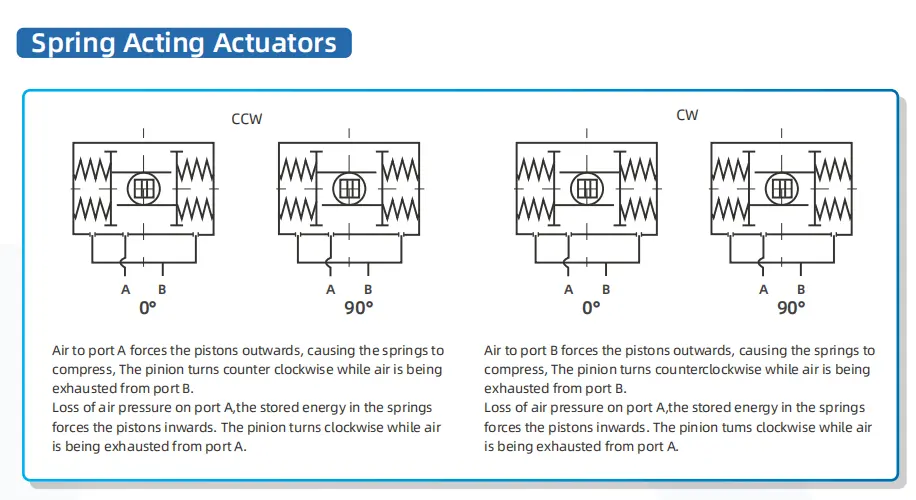

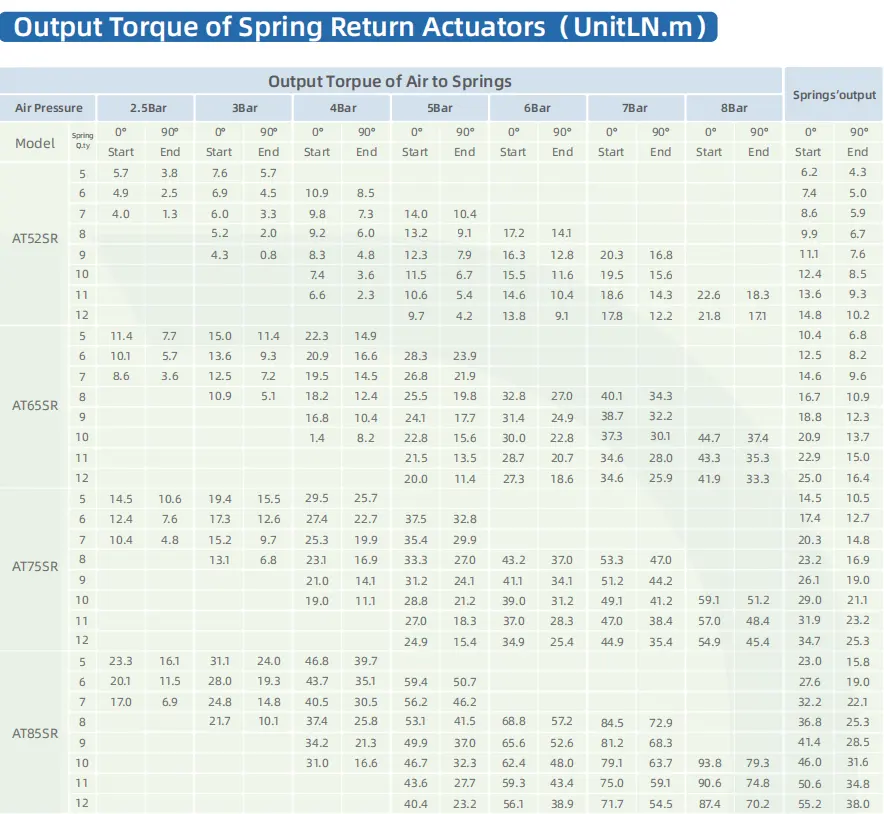

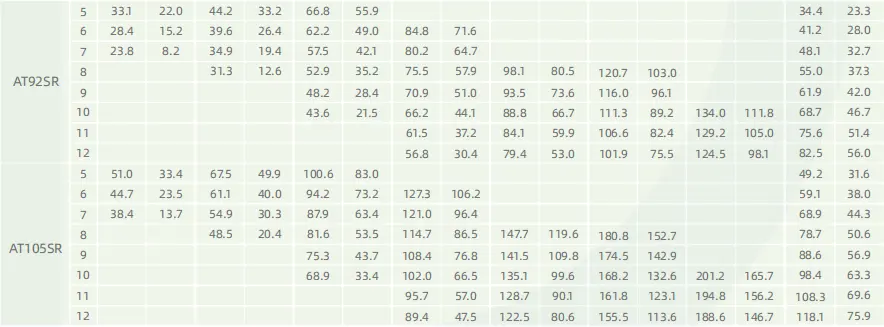

✅Integrated Pneumatic Automation (AT Series):Powered by DELCO’s reliable AT Series Pneumatic Actuator (available in Single Acting or Double Acting). It provides rapid response and precise flow control. The actuator body is designed for clean environments, and standard ISO mounting allows for easy integration of position indicators and solenoid valves.

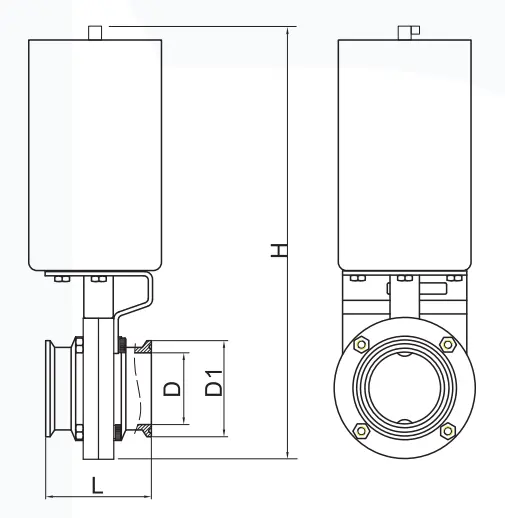

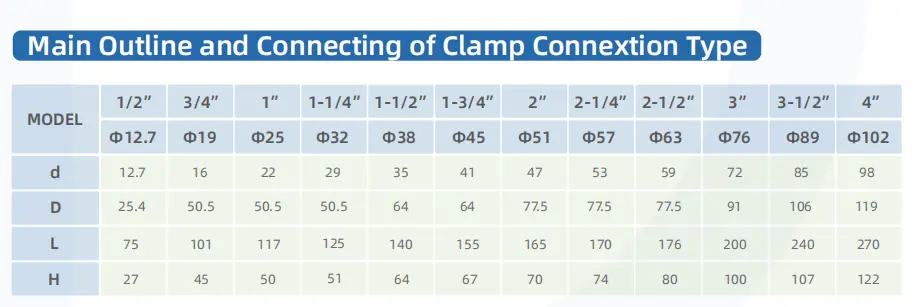

✅Quick-Clamp Connection for Easy Maintenance:The valve utilizes a standardized Clamp Connection (matching generic sanitary sizes 1/2"–4"). This allows for tool-free disassembly within seconds, significantly reducing downtime during routine inspection, cleaning, or seal replacement in high-frequency production cycles.

Photo

Photo

Key Application Fields

-

Oil & Gas

DELCO API-certified valves ensuring safety and reliability in demanding high-pressure pipelines. -

Chemical & Petrochemical

DELCO corrosion-resistant solutions tailored for handling aggressive acids and hazardous fluids safely. -

Power Generation

DELCO solutions efficiently withstand extreme high-temperature and high-pressure steam cycles in power plants. -

Food & Pharmaceutical

DELCO sanitary valves with FDA-compliant, crevice-free designs to ensure absolute product purity. -

Water & Wastewater

Durable municipal solutions by DELCO, designed for zero leakage and long-term sustainability. -

HVAC & District Heating

DELCO valves ensure precise flow regulation to optimize energy efficiency in modern buildings.

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application